How shoes are made (MAMIAN factory tour)

We would like to introduce you to Mamien's factory tour, which is the process of making shoes, which you don't usually see.

Please stay with us until the end.

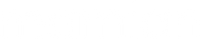

(1) Pattern creation - Make the design into the real thing -

A pattern maker makes a paper pattern based on the design. Shoes designed on a plane become three-dimensional through sample creation.

Even the shoe last and the shape of the heel can greatly change the impression of the shoe.

This process is also an important point for MAMIAN, who are particular about the beauty of the pumps themselves.

② Cutting - Accurately and efficiently cut multiple parts -

There are 100 types of fabrics handled by MAMIAN. The fabric is cut by hand while the craftsmen directly check the mold.

Even in a single pair of pumps, the materials and shapes used vary depending on the parts. The craftsman grasps all of them and works without waste while calculating.

③ Sewing -from plane to three-dimensional-

Sewing with a sewing machine that sews two-dimensional parts together to create a three-dimensional shape.

Depending on the material and color of the shoes, the type of thread is changed, and depending on the situation, the sewing machine is also changed.

It is a work that requires considerable skill because it sews a fabric that is thicker and harder than cloth.

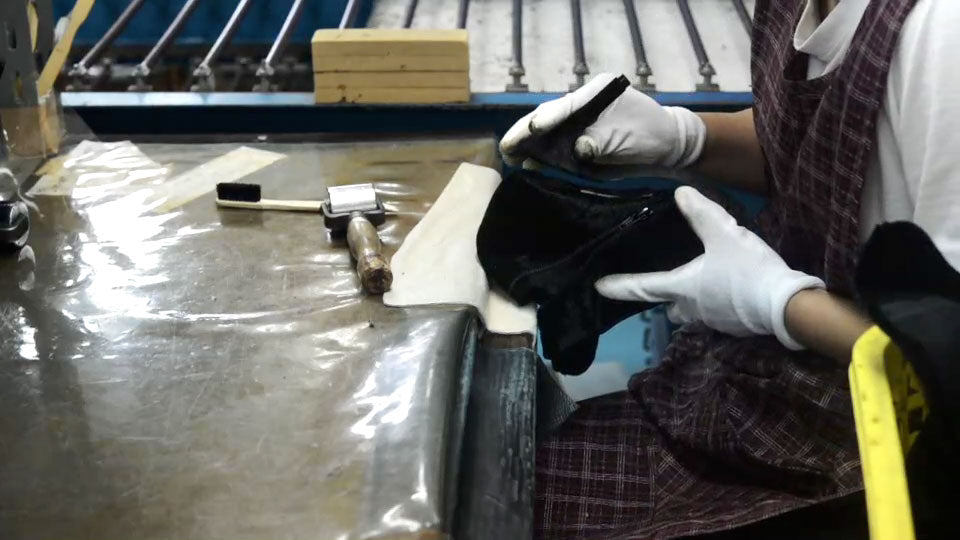

④ Hanging -The first step to form a beautiful form-

Once the upper (instep) is placed on the last with the insole, the shape of the toe is formed by a machine.

By pulling with a strong force, the carapace becomes a shape along the last.

The elasticity and hardness of each material differ, so the skill of the craftsman is tested to adjust the pressure.

After the toe is hung by a machine, it is hung by human hands.

In addition to having to pull the carapace with great force, detailed work is also required to prevent slippage and gaps.

The craftsmen who carry out the hanging work are called “harikou”.

Traditionally, there are many women in the pasting industry because of the detailed work involved, and many female pasting workers are working at MAMIAN.

④ Scraping and putting into the kiln -Creating stable comfort-

It is commonly known as "buffing", which is the work of scraping off the unevenness on the bottom caused by the thickness of the fabric when hanging it.

If the bottom of the pump is not flat, it will greatly affect the comfort. There is no choice but to rely on the sense of craftsmen's hands here.

After shaving, it is placed in a pot and heated.

By applying heat, the carapace conforms to the wooden pattern, creating a beautiful form.

⑤ Back suspension -Forming an elegant and beautiful back view-

Back suspension that forms a back form. Press the heel part flat with a bounding machine.

The heel is an important part of wearing heels. If this part is bumpy, the heel will not stick properly.

⑥ Bottoming and heel strike -For safe high heels that won't break, won't come off-

Apply special strong glue to the bottom and put it in a pot to dry.

As the viscosity of the paste increases as it dries, the bottom is attached to it by hand, starting from the toes.

Pressure is applied with a crimping machine, and the gaps and sides that are easy to float are crimped by hand one by one.

When you remove it from the wooden mold, it's time to hit the heel.

Heels come in a variety of shapes and heights, each with a different type and number of nails.

For safe high heels, a craftsman with enough experience and feeling carefully hits each pair.

⑦ Attaching the insole -Put MAMIAN's name on the finish-

Add an insole to finish.

The shape of the insoles varies depending not only on the shape and size of the pumps, but also on the type of cushion used.

It looks easy, but if you don't train patiently, the insoles of high heels will become distorted.

⑧ Cleaning/Inspection/Packing -Providing the best products to our customers-

Each item is inspected to make sure that there is no glue sticking out and that there are no scratches or stains.

Finally, we pack the pumps so that they are not damaged and send them to the customer.

How was it?

Mamien is one of the few shoe manufacturers that carries out all these operations in Japan (Kobe City, Hyogo Prefecture).